This post describes the bedding of a Remington Model 788 action in a polymer stock.

Nature Quiz: What do geese and people have in common? Answer: They both like to sun themselves next to the water, as these Canada honkers were demonstrating on this sunny, late fall day.

Down to Business

My favorite plain rifle, the Remington Model 788 was produced from 1967 to 1984 in a variety of calibers. In those days your average plain rifle came equipped with a “hardwood” stock. Walnut was rare, but a few Model 788s were produced with walnut stocks.

Common hardwoods for gunstocks, other than walnut, are birch and beech. Both have been used as a substitute for walnut in military rifles. Beech is a very hard wood with small, dark, elongated pores that give it an appearance similar to oak. Yellow birch does not have this quality. I believe that yellow birch, which is used also in furniture, is the wood most often found in the Model 788 and other sporting gunstocks.

The following picture shows a Model 788 .222 with a birch stock. A birch stock is often fairly light in color and has plain, straight grain, although a bit of figure is sometimes present. It may be stained for a darker effect.

Stocks of synthetic material replaced wood for military rifles years ago and the plain, sporting rifle production has followed suit. Go to a rifle range today, and if twenty guys are blazing away on the line, you may not see one stock of wood. In Fact, that was my experience. One day I looked around, and I was the only guy on the line with a wooden handle on his boomer. I immediately thought I was probably perceived as being over the hill and not cool, and, while that is true, I figured that I could do something about it without getting rid of my beloved Remington 788s.

Some years ago, in fact, I had bought a black, plastic stock made by Ramline for my .308 and had never gotten around to try it out. Now, I knew the time had come to put it in service.

There are different ways to fabricate a synthetic stock. The simplest is by injection molding. A thermoplastic material is used. That is a plastic that can be heated to a molten state, then injected into a mold. Upon cooling, the plastic, in original composition, solidifies in its new stock shape. The technique has been around for years, and all kinds of solid plastic objects are made by injection molding. Another method is to use modern composite polymer materials, building them up in layers to form the stock. This produces a lighter, stronger stock that is considerably more expensive, thus appealing to the elites that must have the best, and are willing to pay multi hundreds of dollars.

The Ramline stock is of the injection molded type and is very economical. That was my way to go because the Ramline quality is good, it is sturdy, and it is just as black as any other product. Choice made.

Doing the Work

The actions for which the Ramline is made will drop right in with a good fit. Put in the action screws, go hunting and forget worrying about the weather. This, however, was too simple for me. I wanted the best possible fit and support around the recoil lug, so I decided to glass bed the action and put in pillars for the screws. I used Acra-Glass Gel from Brownell’s and pillar tubes for a Mauser action. These have the right diameter but have to be cut for length to fit the Remington action.

The bedding process proceeded without difficulty. I used modeling clay to fill cavities around the recoil lug area and followed the usual directions for using release agent and mixing the glass gel. I routed the inside level area of the front action screw surface down a bit and cut the front pillar tube to position the action at the right depth when the gel was applied and allowed to set. The fit of the tang at the rear of the stock seemed good and solid, so I did not glass bed that area, but I did cut and glue in a pillar tube for the rear screw. The finished job is shown in the next photo.

The barrel floats in front of the bedding. Some rifle workers would use a shorter bedding support in front of the recoil lug than I did. A rule of thumb is to have no bedding support past the point where the barrel begins to taper, so I think I am OK. Because the plastic stock is really about the same weight as the wooden one, the handling qualities of the gun were changed very little, and the final product looks very much like most of the new, plain, plastic jobs offered by the major firearms companies. The difference, of course, is that this one has the 788 action, which we know is capable of fine accuracy. Will the new stock maximize the accuracy performance? That will have to show up in accuracy testing at the bench.

At the Range

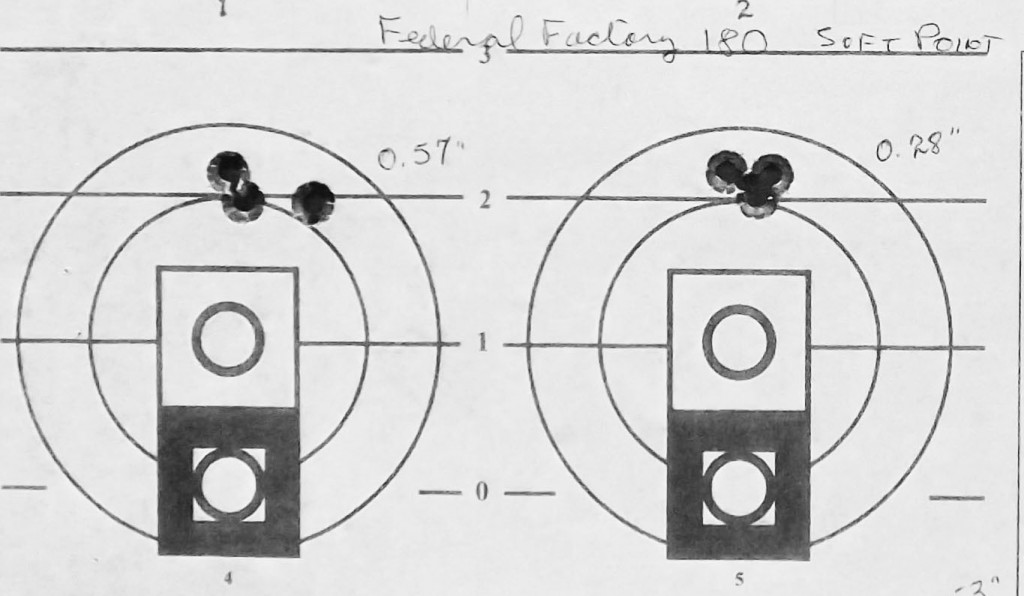

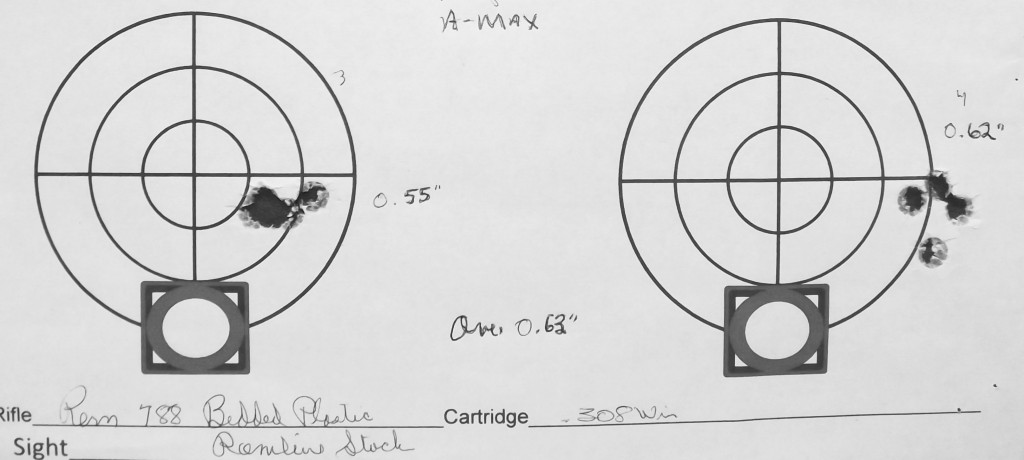

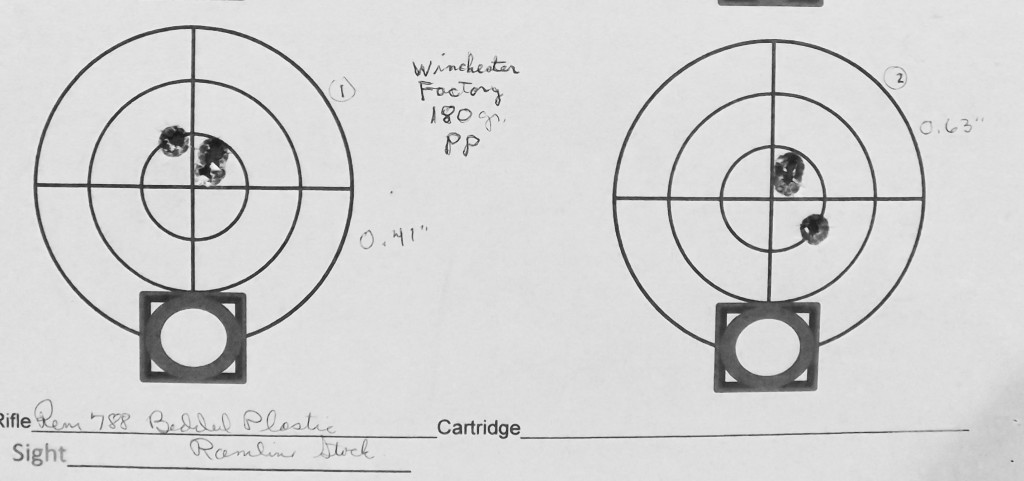

For an accuracy check I fired twelve groups at 50 yards using three different factory loads: Federal 180-gr Soft Point; Hornady Match 168-gr A-Max; Winchester 180-gr Power Point. Two groups of each are shown in the pictures.

The average fifty-yard group size for the 12 factory load groups was 0.56,” or, 1.1 minute-of-angle.

Two handloads were tested. Hornady 180-gr spire points pushed at 2352 fps by W748 gave four groups averaging 0.68″ (1.36 MOA). Best performance was found with 42.6 gr of Varget pushing a Hornady 165-gr flat-base spire point at 2320 fps. Six consecutive groups averaged 0.39″ (0.78 MOA). The smallest measured 0.29″, the largest, 0.46″. This consistency shows that the rifle is happy with is bedding job. There was very little tendency toward fliers with any of the tested loads.

I rate this performance good for a plain rifle, but more experimenting/shooting would give even better results. Handloading is still the best way to get maximum accuracy, and I need to use a wider range of bullets, including some of the Sierras that have given good results in the past. They need to travel a bit faster than the loads tested above did. Hodgdon Varget and IMR 3031 powders will do the trick, I think.

Is it worth the trouble to stock a rifle this way? Maybe not, from the standpoint of pure accuracy. The 788 action well bedded in a wood stock would do as well. However, for the frequent hunter, the bedded Ramline would be extremely stable over a period of time in all kinds of weather.

Oh, I almost forgot why I did it in the first place. The cool image of the black plastic, of course.